We have available a dedicated metal fabrication shop with sophisticated computer controlled equipment to fabricate our own sheet metal. This helps maintain quality, cost and construction deadlines. Our shop includes the latest equipment, including a computer-aided sheet metal brake for precision fabrication of fascias, copings, and flashings.

We work with various gauge metals and various types of metals, ranging from pre-finished galvanized steel and aluminum to copper, stainless steel, and Kynar finished metal from the leading manufacturers.

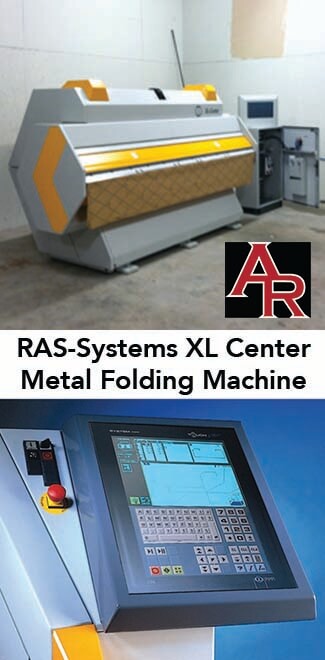

The XL Center will support the bending of tapered metal parts including coping caps, downspouts and gutters. This feature will provide a significant cost savings to our customers. Tapered gutters will allow us to lay one section of a gutter inside another section, making installation much faster.

The XL Center will allow for operators to graphically design metal parts with a touch screen interface and then visualize the part on a screen. By offering folding from the top and bottom, parts can be developed without flipping the metal.

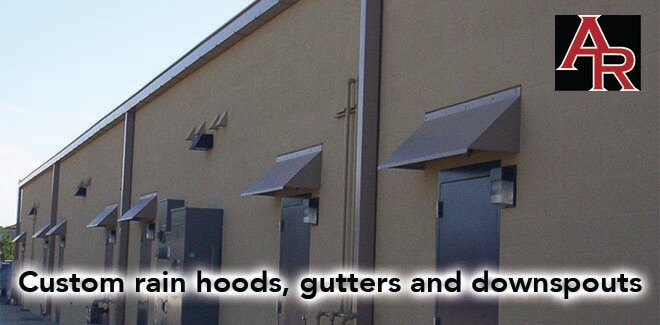

The photo below helps visualize how the metal folding machine can create custom rain hoods, gutters and spouts.